INPUT VOLTAGE AND FREQUENCY

OPERATING CONDITIONS

The motors shown in this catalogue are designed to operate at a maximum ambient temperature of 40°C, maximum altitude of 1000 mt above sea-level and with values of relative humidity between 30% and 95% (without condensation). In different conditions the nominal power changes according to the coefficient of variation indicated in the table.

STANDARDS

TYPE OF SERVICE

INSTALLATION AND COMMISSIONING

General conditions

The electric motor is a device that may cause hazards, mainly of an electrical nature. If used wrongly, it can cause harm to persons, animals and things. Below are some practical suggestions addressed to qualified staff in charge of installing and commissioning the motor.

Daver Motors declines all responsibility for improper use of the motor or failure to observe the EEC Safety Directives concerning electrical material.

Installation

• Check that the motor has not been damaged during transport. Remove any locks or protection used for transport; verify that the shaft turns freely.

• Carefully check that the nominal data on the rating plate correspond to the features of the motor application.

• Pay attention to direct coupling and couplings with pulleys: excessive force can permanently damage the motor bearings. If the coupling is by belt, there must be perfect parallelism between the motor axis and pulley in order to avoid damage and/or vibrations.

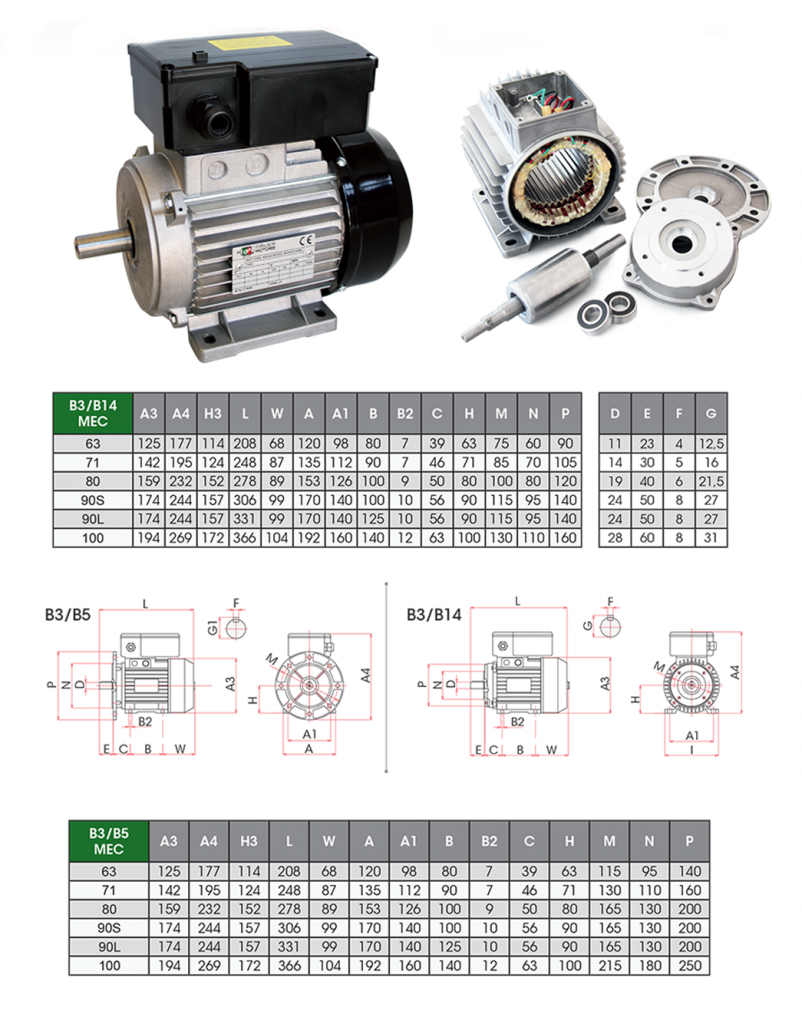

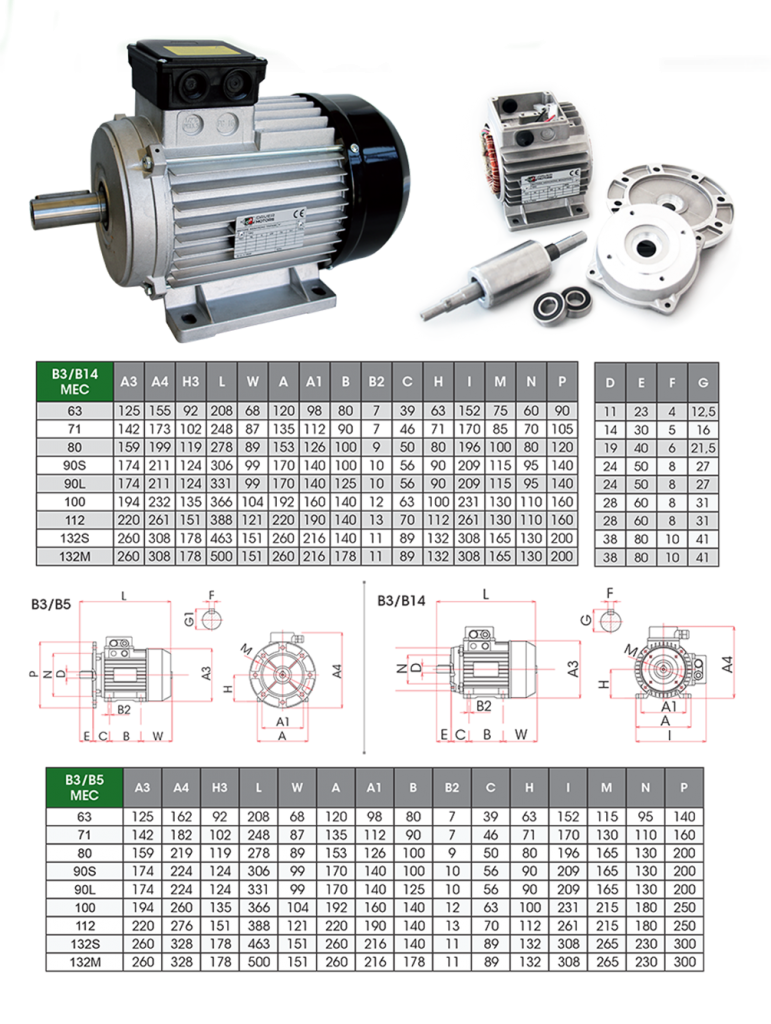

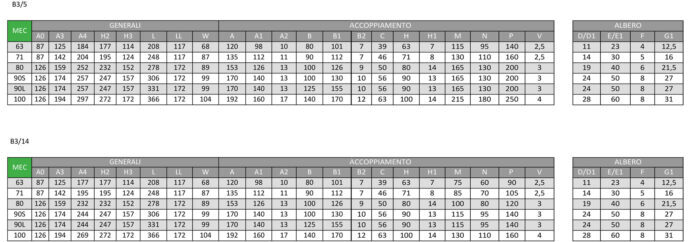

• If the motor has feet (B3 shape), they must be fixed to a solid, perfectly flat surface. The feet may break if they are deformed when tightening the screws.

• On motors with B14 flange and through-holes, the length of the screws should be determined in advance to avoid damaging the motor winding.

Commissioning

• In order to prevent undesirable voltage drops, make sure the power cables are adequately rated in terms of capacity and insulation for full load and starting current.

• In order to safeguard the motor from overloads and short circuits it is advisable to provide appropriate protection circuits. The use of fuses only is not be recommended.

• Bond all equipment to earth in accordance with the standards in force.

• Before coupling ensure that the direction of rotation is correct.

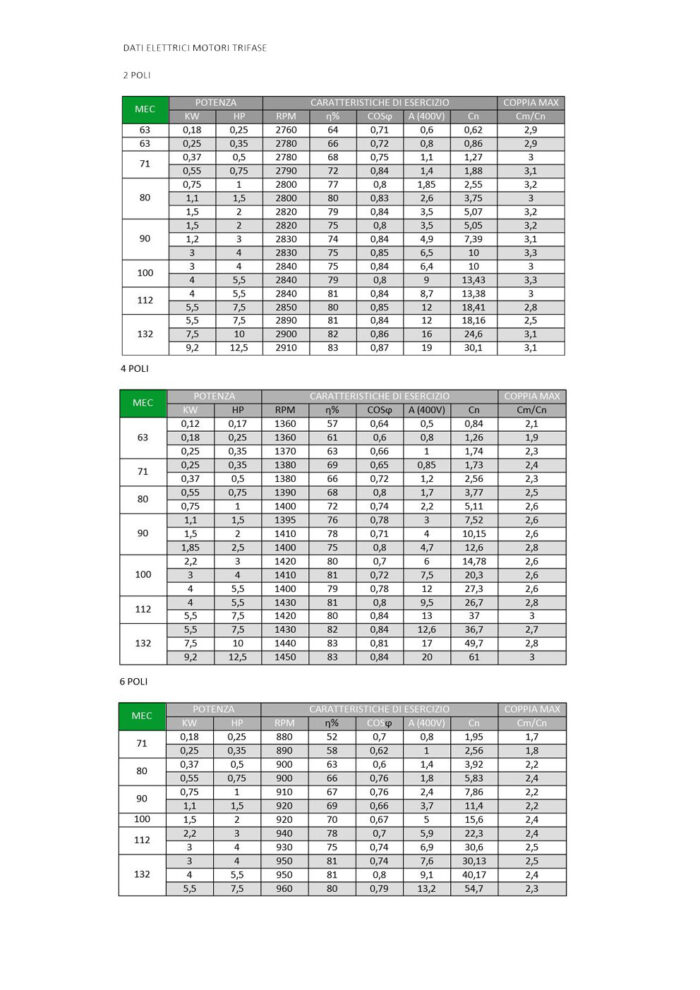

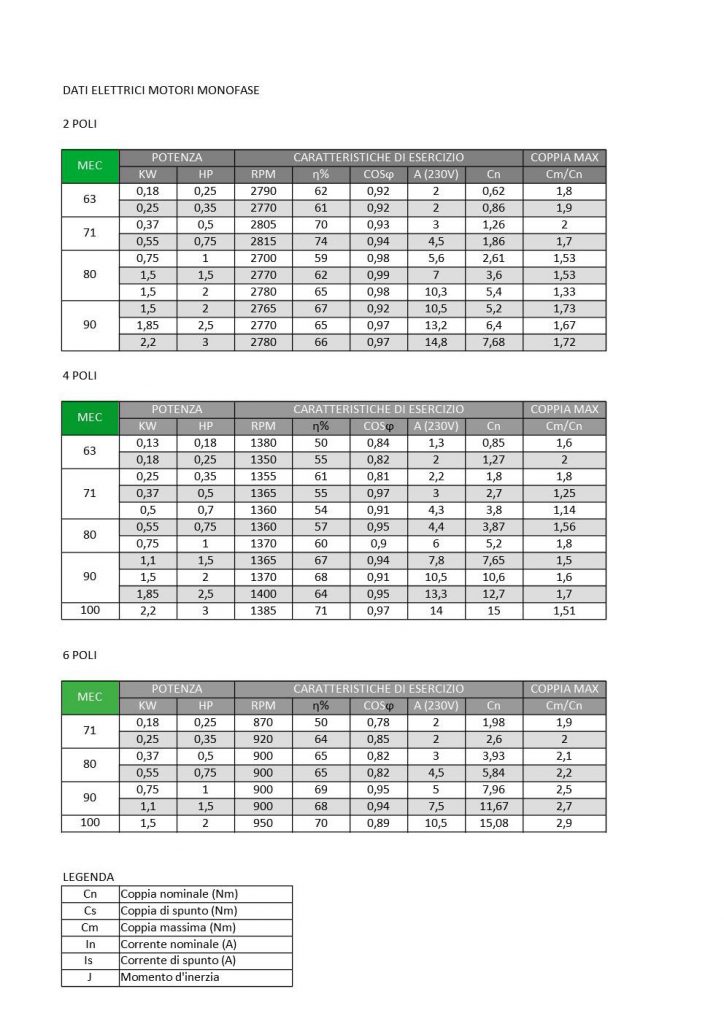

- MOTORI MONOFASE 2-4-6 POLI

- MOTORI TRIFASE 2-4-6-8 POLI